La economía de nuestro país se divide en múltiples áreas que contribuyen a su crecimiento, desde el tamaño de la población hasta los diversos ámbitos de negocio que mantienen un flujo de ingreso constante. En este sentido, la manufactura representa aproximadamente el 20% del PIB que, proviene del sector automotriz, alimentos, bebidas y electrónica.

El impulso que se le brinda a las especialidades de la manufactura y a su orientación exportadora ha permitido que su actividad crezca anualmente

Origen del concepto manufactura

El concepto de manufactura en principio únicamente se refería a la forma de producción artesanal. Sin embargo, la introducción de nuevos métodos productivos, la aplicación de las tecnologías y el crecimiento de las industrias comenzaron a modificar esta idea inicial.

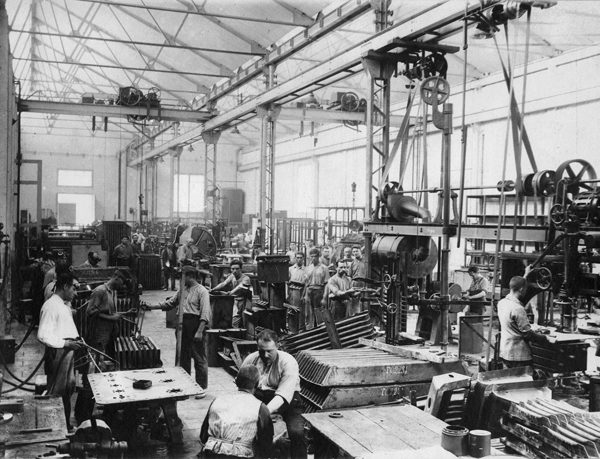

La Revolución Industrial fue un proceso de transformación económica, social y tecnológica que se presentó en la segunda mitad del siglo XVIII en el Reino Unido. Este movimiento rápidamente comenzó a expandirse por todo el mundo y de esta manera, fue que el concepto de manufactura se adaptó a las nuevas prácticas.

Definición de manufactura

A partir de ese acontecimiento histórico se estableció una definición universal para este concepto y fue así como se determinó a la manufactura como una actividad perteneciente al sector secundario de la economía. Es decir, es la fase dedicada a la producción de bienes.

El proceso de manufactura sucede gracias a dos componentes: las materias primas y la actividad humana. De este modo, la compenetración de ambos permite abarcar desde la artesanía hasta la alta tecnología aplicada en el sector industrial.

El objetivo fundamental de la manufactura es transformar toda materia prima en productos manufacturados, productos elaborados o productos terminados para su distribución y consumo a gran escala

Procesos de manufactura

A lo largo de la historia, el hombre siempre se ha mantenido curioso ante los diversos materiales que se encuentran en el mundo y con el paso del tiempo fue conociendo las características de cada uno y de esta manera aprendió a dominar distintas técnicas que le ayudaron a transformarlos en elementos útiles para su existencia.

Esto vislumbró la aparición de las primeras industrias como la farmacéutica, textil, metalmecánica, entre otras. Es así como este fenómeno dio origen a la manufactura que apareció como un método especializado y a sus procesos de fabricación.

Principales tipos de procesos de manufactura

Todos los materiales que se someten al proceso de manufactura se pueden diferenciar por sus características que determinan su resistencia, tamaño, forma, densidad, etc. Para crear un producto elaborado cada uno de ellos pasa por una serie de operaciones que se pueden dividir en dos principales grupos:

Proceso continuo

Este tipo de manufactura se caracteriza por la producción de lotes de productos, ya sea por cantidad o peso, cuyo cálculo se efectúa por medio de variables de rango continuo. Estas variables comprenden carácter físico o químico como peso, resistencia, volumen, color, conductividad, transparencia, etc.

Los procesos continuos los podemos ver en la producción de acero, gasolina, minerales y gases industriales.

Proceso discreto

En este se fabrican piezas, partes o ensamblajes que se pueden contabilizar de manera sencilla y además, facilita la clasificación de productos que, según sus atributos admisibles o desventajosos, se determina su calidad. De este modo, cada atributo puede ser medido por una escala discontinua, de numeración o simple conteo.

En este proceso entra la fabricación de parte de automóviles, la manufactura de circuitos electrónicos.

A partir de estos procesos tradicionales, surge uno adicional con el objetivo de mejorar la labor productiva.

Proceso de manufactura flexible

Un proceso de manufactura flexible es aquel que se utiliza para combatir los niveles de variación que se presentan en los estilos de productos o partes. Se lleva a cabo de manera independiente para no interrumpir el procedimiento completo de fabricación, mientras se realizan los cambios necesarios.

Este sistema flexible identifica todas las unidades de trabajo para ejecutar correctamente cada operación y permite efectuar cambios de instrucciones de manera diligente. De esta manera, se optimiza la fabricación de diferentes productos a los que se les pueden hacer ajustes inmediatos.

Manufactura de clase mundial

Desde hace unos años la economía ha experimentado una internacionalización, lo cual ha impactado a empresas locales y ha llevado a gran parte del mercado mundial hacia la demarcación de lo que se conoce como empresas globales. En este sentido, se asevera la permanencia de los competidores de clase mundial que respondan a las necesidades exigentes de los clientes.

El término de manufactura de clase mundial hace referencia a las prácticas que implementan las empresas dedicadas a la elaboración de productos para alcanzar un nivel superior en los estándares de flexibilidad, eficiencia y calidad, ya que estos les permiten competir en mercados internacionales.

Es un concepto relacionado estrechamente con los modelos de producción desarrollados después de la Segunda Guerra Mundial nombrados bajo el concepto de manufactura esbelta.

Actualmente la manufactura de clase mundial es un reto empresarial, del cual cada vez más empresas buscan formar parte aumentando la flexibilidad y eficiencia de sus operaciones basadas en la responsabilidad y experiencia de las personas involucradas.

Manufactura esbelta

También conocida como Lean manufacturing es una producción basada en la minimización de pérdidas de los sistemas de manufactura y en la maximización del valor del producto para el cliente. Emplea únicamente los recursos necesarios para el desarrollo.

Al suprimir gastos en activos de bajo valor, se mejora la calidad y se reducen tiempos y costos en la producción

Los principios clave de la manufactura esbelta son:

- Mejora continua.

- Calidad sin margen de error.

- Producción variada, diligente y eficiente.

- Eliminación de actividades sin valor añadido.

- Construcción y mantenimiento de relaciones a largo plazo con proveedores.

- Procesos pull. Se producen sólo los productos que serán “jalados” por los clientes.

Rasgos de la producción por manufactura

Como lo hemos mencionado a lo largo de esta entrada, un proceso por manufactura tiene la principal función de transformar diversas materias primas para obtener múltiples productos.

Detrás de cada proceso existe una necesidad por parte de un público concreto, es ahí donde radica la razón de ser de cada uno. Ante las demandas del mercado se encargan de abastecerlas en tiempo y forma.

Un proceso por manufactura comprende cinco etapas:

- Manejo de las materias primas.

- Acondicionamiento físico de los recursos.

- Transformación por procesos químicos.

- Clasificación de acuerdo a sus características.

- Elaboración de productos.

De manera general, el concepto de manufactura posee los siguientes rasgos que la distinguen:

- En función de la complejidad de elaboración del producto, las acciones manufactureras pueden requerir un mayor o menor número de procesos de producción intermedia.

- Cada proceso implica la actividad humana como técnica artesanal y así también, se vale de maquinaria y tecnología.

- Los procesos son variados y divergentes, por lo que se segmenta cada uno a su respectiva especialización de actividades.

- La optimización de los recursos es su primacía y como consecuencia las empresas reciben diversos beneficios.

Principales sectores de la manufactura

A partir de la transformación de materias primas se obtiene una amplia variedad de productos. Por ello,en este proceso la tecnología se ha convertido en protagonista debido a su función sobresaliente de mejorar las actividades productivas para contribuir en la elaboración de productos de calidad que cubren las exigencias del sector.

Hoy en día, la manufactura posee una diversidad de operaciones que se ve enriquecida por la aplicación de tecnología de punta, lo cual ha hecho posible dividir cada sector de acuerdo a sus actividades y el producto final que producen.

Algunos de los principales sectores manufactureros son:

Metalmecánica

Nuestro país se encuentra dentro de los primeros lugares de la lista de países importadores de maquinaria y herramienta en el mundo, resultado del impulso que le otorga el sector automotriz y aeronáutico por medio de la fabricación de productos metálicos.

Visual México optimiza la gestión y el desarrollo de las empresas encargadas de elaborar y ensamblar materiales a través de la solución específica: ERP Industria metal mecánica.

Automotriz

Este sector gracias a su dinamismo y competitividad ha logrado una producción sostenible de vehículos y autopartes. Además, es uno de los sectores que en los últimos años ha aumentado su fortaleza al implementar procesos innovadores.

Nosotros desarrollamos un ERP Automotriz, el cual otorga a las empresas una producción rápida y efectiva enfocada en los principales retos del mercado que requieren de soluciones innovadoras para la fabricación de productos de calidad.

Farmacéutico

La producción de medicamentos ha incrementado sus valor en la economía del país, es por ello que ha experimentado un desarrollo constante en el aumento de sus niveles productivos que favorecen su relación con la exportación y su apertura comercial.

En Visual México sabemos que este es un de los sectores que mantienen sus actividades bajo constantes regulaciones que determinan la aprobación sanitaria de los medicamentos, así como su venta. Por ello, nuestro ERP Industria farmacéutica otorga un valor de calidad superior a las empresas del sector salud.